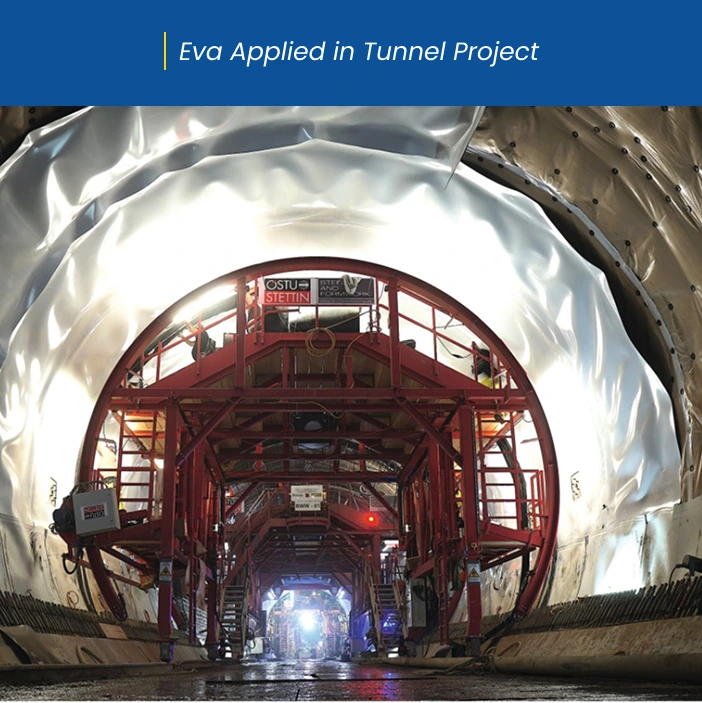

Weidun® 008 EVA Waterproofing Membrane

Weidun® 008 EVA Waterproofing Membrane is a kind of anti-seepage material composed of high molecular polymer as the basic material, which can prevent liquid leakage and gas volatilization. Its a thin, flexible, and impermeable sheet made from a combination of ethylene and vinyl acetate polymers.

Uses:

- Tunnel waterproofing projects

- Highway projects

Contact Our Representatives

Weidun is committed to transparency and sustainability. Please fill out the form below, and our experts will get in touch with you.

Features & Benefits

Superior Durability

Strong, durable and manufactured to consistent dimensions

Fully Bond

Creates a strong chemical and mechanical bond to concrete, which prevent any lateral water migration

OEM Available

Offer superior performance based on your region's unique climate needs

Product Details

Weidun® 008 EVA Waterproofing Membrane is a kind of anti-seepage material composed of high molecular polymer as the basic material, which can prevent liquid leakage and gas volatilization.

Its a thin, flexible, and impermeable sheet made from a combination of ethylene and vinyl acetate polymers.

Excellent crack resistance

Excellent weather resistance

Strong elasticity, light specific gravity, high elongation

No open flame, easy to apply

Uses

Weidun® 008 EVA Waterproofing Membrane is designed for tunnel waterproofing project.

How To Use

Surface Preparation

The surface of the tunnel walls and floor need to be cleaned and prepared for the application of the EVA waterproofing membrane. This may involve removing any existing coatings, smoothing out any rough areas, and ensuring that the surface is dry and free of debris.

Primer application

A primer is typically applied to the prepared surface in order to promote adhesion between the surface and the EVA waterproofing membrane. The primer may need to cure for a specified period of time before the next step can be taken.

Membrane Installation

The EVA waterproofing membrane is then applied to the prepared and primed surface using an adhesive or heat-welding method. The membrane is typically rolled out and cut to fit the dimensions of the surface, with care taken to ensure that it is installed without any wrinkles or bubbles.

Seaming

The seams between adjacent sheets of EVA waterproofing membrane need to be sealed in order to prevent water from seeping through. This may be done using heat welding or by applying a separate sealing tape.

Backfilling

Once the EVA waterproofing membrane has been installed and inspected, the tunnel can be backed with soil or other materials as necessary.

Advantages

- Excellent water resistance -suitable for applications where water pressure is high, such as tunnels

- Flexibility – can be bent and wrapped around complex tunnel geometries, ensuring a tight seal and preventing water intrusion

- Durability -resistant to degradation from UV light, chemicals, and extreme temperatures,ensuring, a long service life

- Cost effective- Especially for large tunnel project.

Storage and Handing:

To prevent damage, support rols on end in an upright position and store in a clean,dry location, covering as necessary to protect from environment damage.

Monitor environmental conditions during storage, handing and application.

Technical Data Sheet

Property | Standard Minimum Value | Weidun Value |

Roll Length min(m) | 10 | 10.01 |

Tensile Strength at 23°c (N/50mm) | 300 | 357 |

Elongation at 23°C +/-2°C, (%) | 300 | 400 |

Adhesive strength at 23°C (N/50mm) | 1.5 | 1.5 |

Low temperature flexibility, at-20°C | No crack | No crack |

Peel strength between membrane and overlap (N/mm) | 1.0 | 1.0 |

Puncture resistance (N) | 350 | 398 |

Oil pereability / number of sheets | 0 | 0 |

Heat resistance, at 80°C, 2 hours | No drop | No drop |

Water penetration (Maintain a water pressure of 0.3MPa for 120 minutes) | Non- penetration | Non-penetration |

Product Specifications

Roll Size* | Customizable |

Roll Length | Customizable |

Roll Width | 3.0m |

Pail Weight | Customizable |

Full Pallet | Weight N/A |

Throughout the construction process, it is important to follow best practices for safety and quality, including wearing appropriate personal protective equipment, ensuring proper ventilation in enclosed spaces, and following the manufacturer’s instructions for product application and handling.

Browse Related Products

Weidun® 005 TPO Roofing Membrane

Weidun® 006 HDPE Waterproofing Membrane