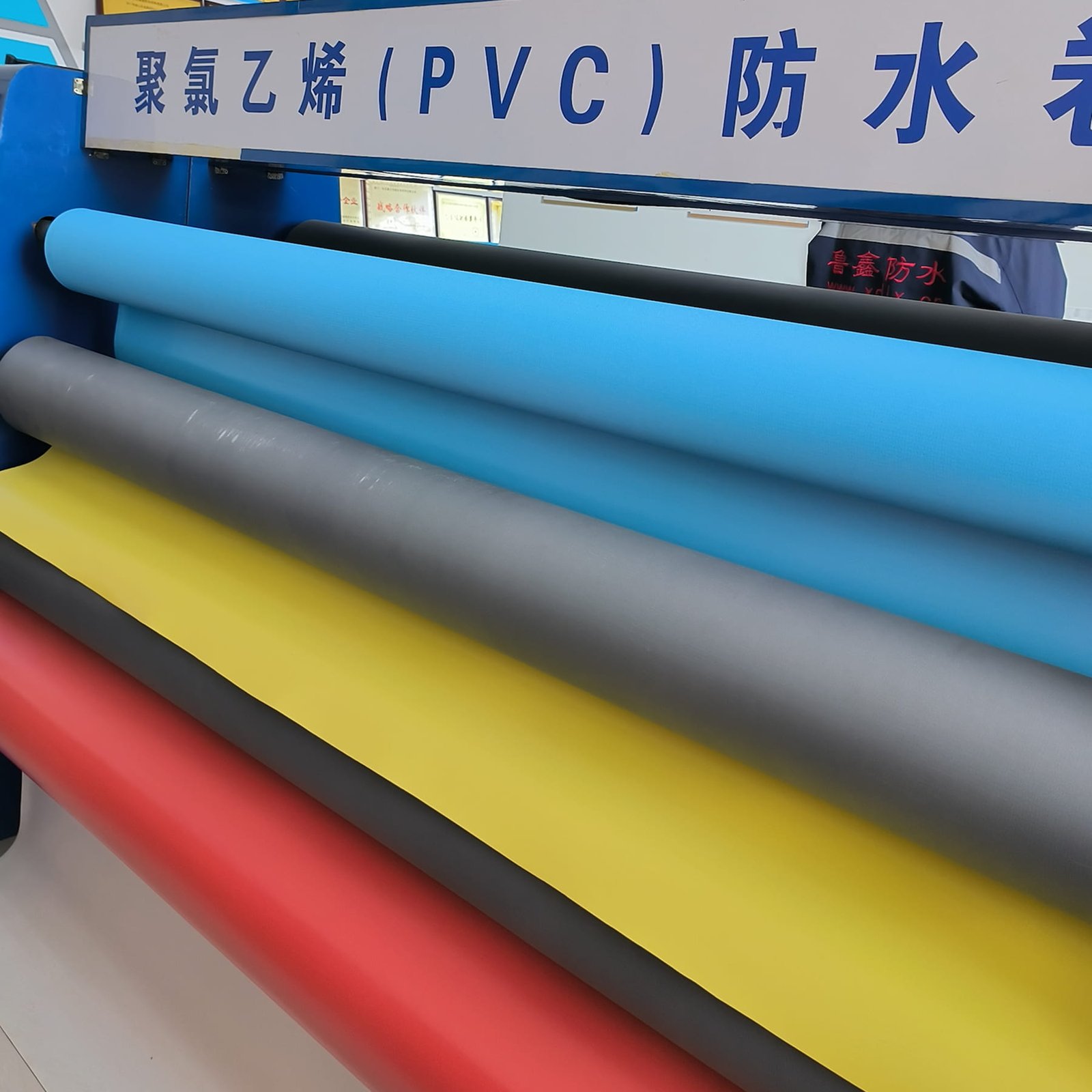

Weidun® 007 PVC Waterproofing Membrane

Weidun® 007 PVC Waterproofing Membrane is made from a combination of polyvinyl chloride (PVC) and other additives. PVC has become extremely popular in recent years, presenting an upward trend in the waterproof market.

Uses:

- Metal roofs, Tunnel waterproofing

- Underground, Landfill

Contact Our Representatives

Weidun is committed to transparency and sustainability. Please fill out the form below, and our experts will get in touch with you.

Features & Benefits

Superior Durability

Strong, durable and manufactured to consistent dimensions

Fully Bond

Creates a strong chemical and mechanical bond to concrete, which prevent any lateral water migration

OEM Available

Offer superior performance based on your region's unique climate needs

Product Details

Weidun® 007 PVC Waterproofing Membrane is made from a combination of polyvinyl chloride (PVC) and other additives. PVC has become extremely popular in recent years, presenting an upward trend in the waterproof market.

Uses

Weidun® 007 PVC Waterproofing Membrane is used to prevent water and moisture from penetrating a building’s exterior or interior surfaces

Advantages

Durable: resistant to wear and tear, and can

with stand harsh weather conditions

Flexible: They can be stretched and bent without cracking or breaking

Versatile: PVC waterproofing membranes can be used in various applications and environments

Easy to install: They can be installed using various methods, such as adhesion, clamping, or welding.

Cost effective: PVC waterproofing membranes are generally less expensive than other materials

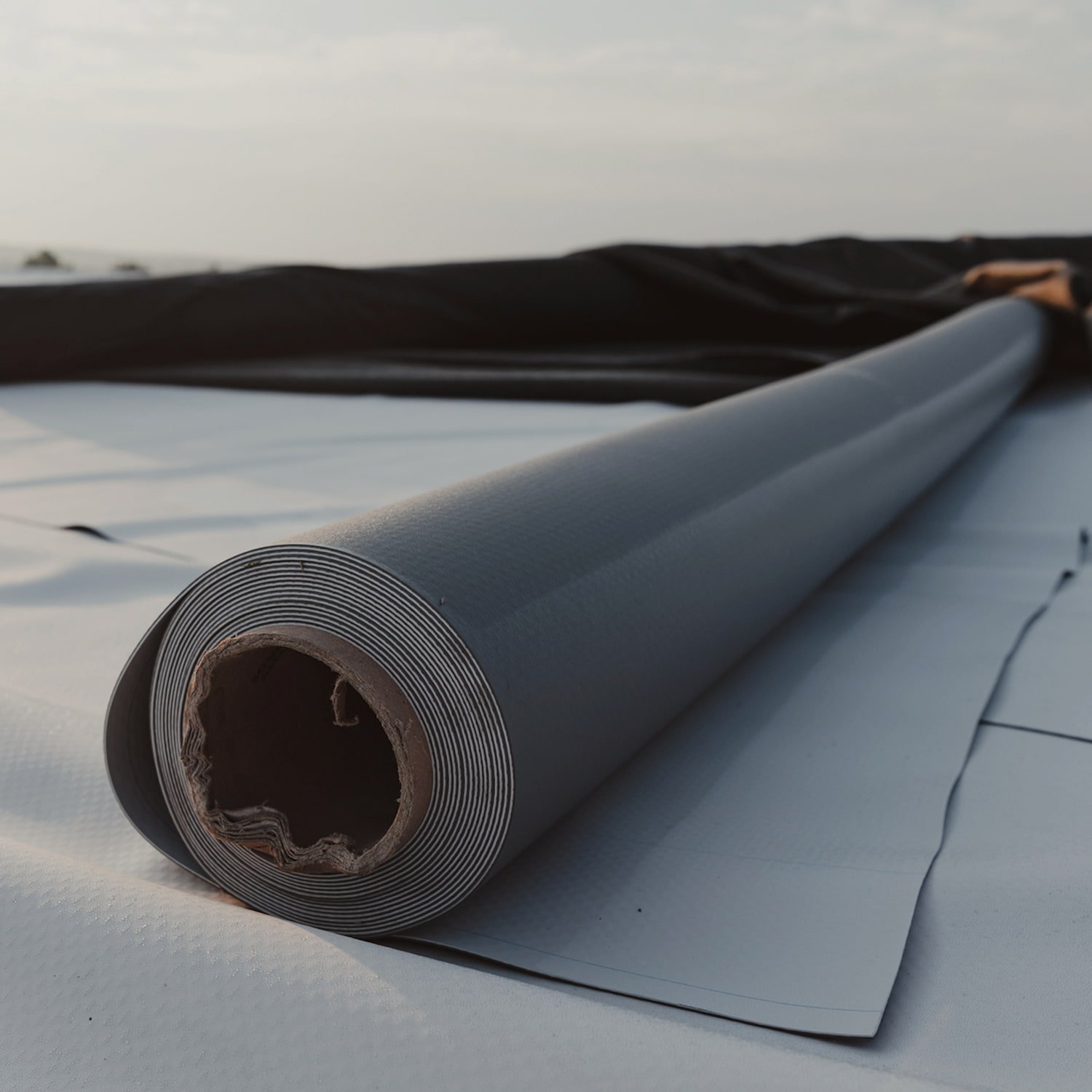

Storage and Handing:

To prevent damage, support rolls on end in an upright position and store in a clean,dry location, covering as necessary to protect from

environment damage.

Monitor environmental conditions during storage, handling and application

Technical Data Sheet

Property | Standard Minimum Value | Weidun Value |

Roll Length min(m) | 10 | 10.02 |

Tensile Strength at 23°c (MPa) | 300 | 357 |

Elongation at 23°C +/-2°C, (%) | 15 | 20 |

lmpact resistance at 23°C +/-2°C, (1.0mm, N) | 0.5kg m Non-penetration | Non-penetration |

Low temperature flexibility, at -20°C | No crack | No crack |

Peel strength between membrane and overlap (N/mm) | 100 | 105 |

Water penetration (Maintain a water pressure of 0.3MPa for 120 minutes) | Non-penetration | Non-penetration |

Heat treatment dimensional changes (%) | < 2.0 | 1.3 |

Product Specifications

|

Roll Size* |

10.0m2 |

|

Roll Length |

10.0m |

|

Roll Width |

3.0m |

|

Pail Weight |

45.0 kg |

|

Pails per Pallet |

30 |

|

Full Pallet Weight |

1.35 tonn |

Weidun® 007 PVC Waterproofing Membrane installation process involves surface preparation, priming, cutting and positioning, heating and bonding, sealing, and the installation of a protective layer. Careful attention to each step is necessary to ensure a high-quality and long-lasting waterproofing system.

Browse Related Products

Weidun® 005 TPO Roofing Membrane

Weidun® 006 HDPE Waterproofing Membrane