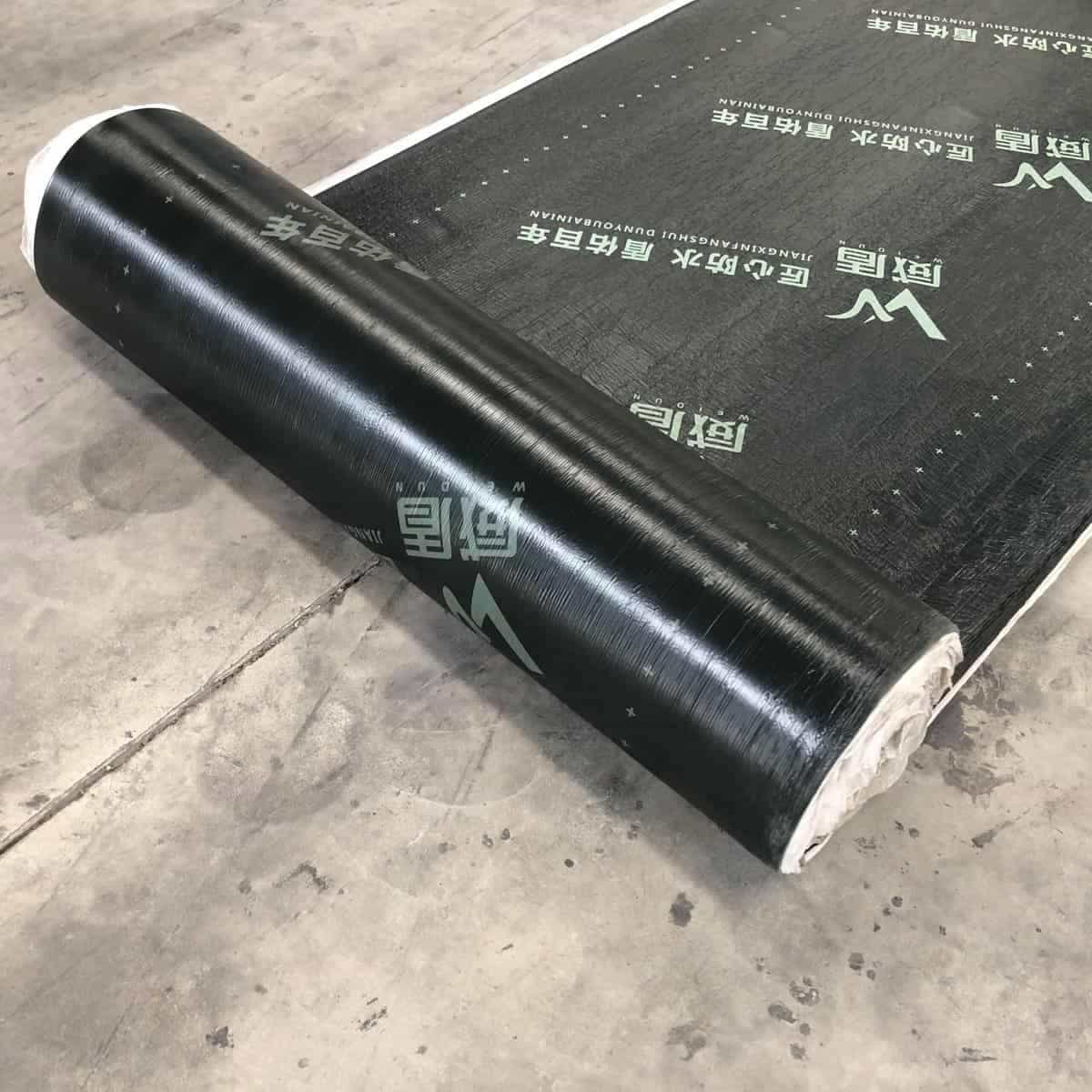

SBS Modified Bitumen Membrane

SBS Modified Bitumen Waterproof Membrane is a strong, resilient, non-woven polyester mat that is coated with flexible, polymer-modified asphalt and is smooth.

It is a time-proven system that has been around for decades due to its reliable performance.

Area of Application:

It is widely used in:

- Roofing solutions in the industry

- Subway, tunnel, highway, bridge and etc

Data Sheet

Contact Our Representatives

Weidun is committed to transparency and sustainability. Please fill out the form below, and our experts will get in touch with you.

Features & Benefits

Superior Durability

Lasting Value

OEM Available

Product Details

SBS Modified Bitumen Waterproof Membrane is a strong, resilient, non-woven polyester mat that is coated with flexible, polymer-modified asphalt and is smooth.

Weidun Waterproof has a full line of SBS Modified Bitumen Waterproof Membrane.

Due to its elongation characteristics, a resilient polyester mat core allows it to resist splits and tears.

Specially formulated modified asphalt gives a lasting performance.

Easy to apply by torching.

Available guarantee of up to 20 years.

Application

Technical Data Sheet

Property | Standard Minimum Value | Weidun Value |

Thickness min, mils(mm) | > 4.0 | 4.13 |

Length min, meter (m) | > 9.98 | 10.08 |

Bottom coating thickness, heat welding application products, min. mils(mm) | 1 | 1.1 |

Soluble content, (g/m2) | > 2900 | 3194 |

Tensile strength at 23°C +/-2°C, (N/50mm) | > 500 | 975 |

Elongation at break at 23°C +/2°C, (%) | > 30 | 48 |

Tear strength at 23°C +/-2°C, (N/50mm) | 156 | 333 |

Low temparature flexibility, max, °C | -18 | -20 |

Quality loss after heating conditioning, (%) | < 1 | 0.2 |

Water penetration (Maintain a water pressure of 0.3Mpa for 30 minutes) | Non-penetration | Non-penetration |

Dimensional stability max (%) | 0.5 | 0.03 |

Compound stability at 102°C | No failure | No failure |

Product Specifications

Roll size* | 10.0m2 |

Roll Length | 10.0m |

Roll Width | 1.0m |

Roll Thickness | 3.0mm; 4.0mm |

Roll per Pallet | 30 |

Full Pallet Weight | 1.3 ton, 1.5 ton |

Top side Surfacing | PE Film |

Bottom Side Surfacing | PE Film |

SBS Modified Bitumen Membrane installation process involves surface preparation, priming, cutting and positioning, heating and bonding, sealing, and the installation of a protective layer. Careful attention to each step is necessary to ensure a high-quality and long-lasting waterproofing system.

Browse Related Products

Weidun® 001 PE Smooth Bitumen Membrane

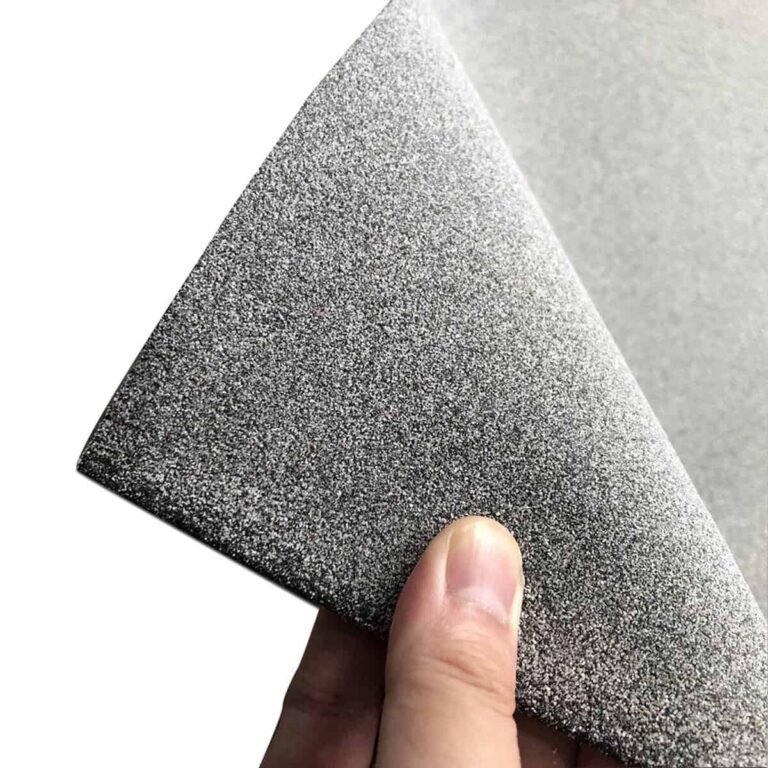

Weidun® 002 PE Granule Bitumen Membrane