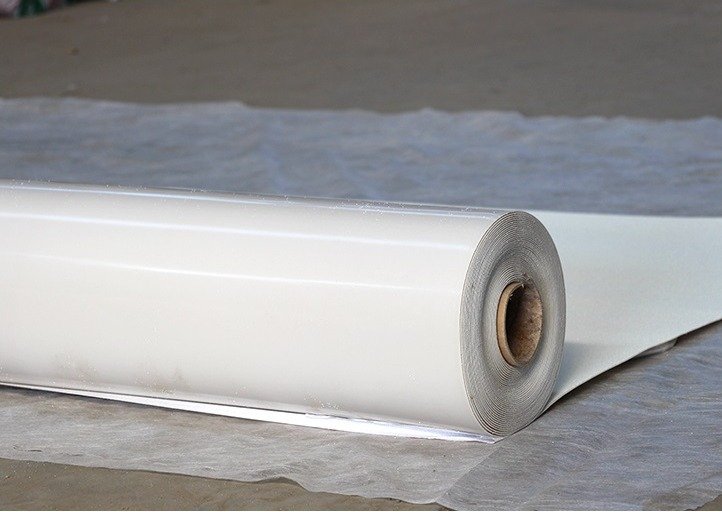

Weidun® 005 TPO Roofing Membrane

Weidun® 005 TPO Roofing Membrane stands for thermoplastic polyolefin, which is a type of single-ply roofing membrane material. TPO roofing is known for its durability, flexibility, and resistance to ultraviolet light and chemical exposure.

Uses:

- Commercial roofing application

- Residential roofing application

Contact Our Representatives

Weidun is committed to transparency and sustainability. Please fill out the form below, and our experts will get in touch with you.

Features & Benefits

Superior Durability

Strong, durable and manufactured to consistent dimensions

Fully Bond

Creates a strong chemical and mechanical bond to concrete, which prevent any lateral water migration

OEM Available

Offer superior performance based on your region's unique climate needs

Product Details

Weidun® 005 TPO Roofing Membrane stands for thermoplastic polyolefin, which is a type of single-ply roofing membrane material. It’s commonly used in commercial and residential roofing applications. TPO roofing is known for its durability, flexibility, and resistance to ultraviolet light and chemical exposure.

Uses

Weidun® 005 TPO Roofing Membrane is considered a good option for single-ply roofing systems due to its excellent physical properties, ease of installation and minimization of maintanece.

Advantages

- Highly durable and resistant to punctures, tears, and impacts.

- Excellent resistance to UV radiation, ozone, and chemical exposure, ensuring longevity.

- Flexible, allowing for easier installation and adaptability to a variety of roof designs and shapes.

- Heat-welded seams create strong bonds, enhancing the overall strength of the roofing system.

- Recyclable, making it an environmentally conscious choice compared to some other roofing materials.

Storage and Handling

To prevent damage, support rolls on end in an upright position and store ina clean, dry location, covering as necessary to protect from environment damage. Monitor environmental conditions during storage.

Technical Data Sheet

Item | Standard Specification | Test Results | Evaluation | ||

Tensile Performance | Tensile Strength / MPa | Longitudianl | ≥ 12.0 | 15.8 | Qualified |

Transverse | 14.7 | Qualified | |||

Elongation at Break, % | Longitudianl | ≥ 500 | 538 | Qualified | |

Transverse | 522 | Qualified | |||

Thermal Treatment Dimensional Change Rate, % | Longitudianl | ≤ 2.0 | 1.2 | Qualified | |

Transverse | 1.3 | Qualified | |||

Low Temprature Flexibility | No cracks at -40°C | No cracks | Qualified | ||

Impreviousness | 0.3 Mpa,2h Watertight | Water tight | Qualified | ||

Impact Resistance | 0.5kg . Mno water seepage | No water seepage | Qualified | ||

Joint Peel Strength, N/mm | 4.0 or membrane failure | 4.0 | Qualified | ||

Angle Tear Strength, N/mm | ≥ 60 | 67 | Qualified | ||

Water Absorption (70°C, 168h), % | ≤ 4.0 | 0.8 | Qualified | ||

Product Specifications

Roll Size* | 20.0m |

Roll Length | 10.0m |

Roll Width | 2.0m |

Roll Thickness | 12mm; 1.5mm |

Top side Surfacing | Smooth; Fleeced-back |

Bottom Side Surfacing | Smooth; Self-adhesive |

Weidun® 005 TPO Roofing Membrane installation process involves surface preparation, priming, cutting and positioning, heating and bonding, sealing, and the installation of a protective layer. Careful attention to each step is necessary to ensure a high-quality and long-lasting waterproofing system.

Browse Related Products

Weidun® 006 HDPE Waterproofing Membrane

Weidun® 007 PVC Waterproofing Membrane