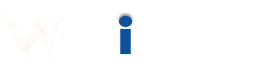

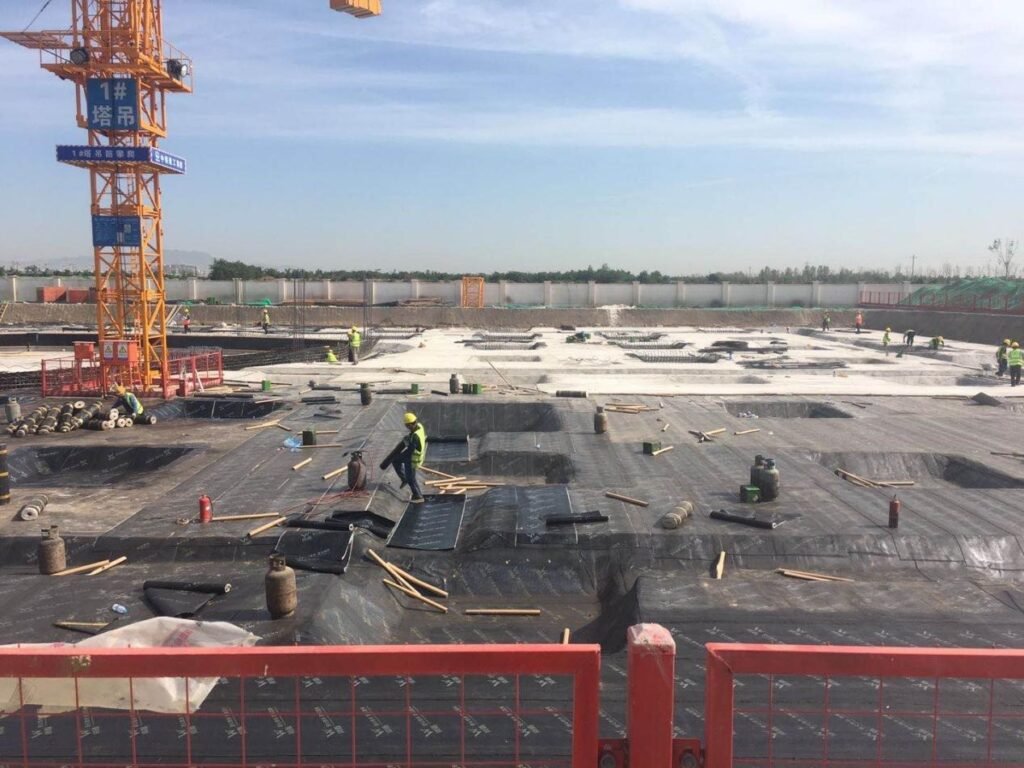

Why Overlap Treatment Is Critical for Bitumen Waterproofing Membranes ?

In SBS modified bitumen and self-adhesive bitumen waterproofing systems, overlap areas are the most common source of leakage. Although these membranes provide excellent waterproofing performance, improper overlap treatment can significantly reduce their effectiveness.

A correctly treated overlap must form a continuous waterproof layer, matching the membrane’s strength, flexibility, and durability. For SBS and self-adhesive systems, this depends heavily on temperature control, material compatibility, and installation accuracy.

Key Preparation Steps Before Treating Bitumen Membrane Overlaps.

Substrate Condition and Cleanliness.

The substrate at overlap zones must be solid, clean, and free from dust, oil, moisture, or loose particles. Contaminants directly affect bitumen adhesion and bonding strength.

Surface Dryness and Temperature Control.

For SBS membranes and self-adhesive bitumen membranes, surface dryness is essential. Excess moisture or low temperatures may weaken bonding performance, especially for self-adhesive layers.

Selection of Compatible Materials.

Overlap materials such as bitumen sealants, seam tapes, or primers must be fully compatible with SBS or self-adhesive bitumen membranes to ensure long-term waterproofing stability.

Standard Overlap Treatment Process for SBS & Self-Adhesive Membranes.

Pre-Laying and Accurate Alignment.

Before bonding, membranes should be dry-laid to confirm alignment. Overlaps must remain straight, flat, and free from folds or tension.

Heating or Activation (for SBS Membranes).

For torch-applied SBS membranes, the overlap area must be evenly heated until the bitumen reaches proper bonding condition. Overheating should be avoided to prevent material damage.

Adhesive Bonding (for Self-Adhesive Membranes).

For self-adhesive bitumen membranes, firm pressure is required to activate the adhesive layer. Rollers should be used to ensure full contact and eliminate trapped air.

Compaction and Sealing.

After bonding, overlaps must be compacted using rollers or flat tools. Bitumen should slightly extrude along the seam edge, indicating proper bonding.

Reinforcement at High-Risk Areas.

Critical areas such as corners, edges, drains, and movement joints should be reinforced with additional sealing tape or bitumen sealant to enhance waterproofing reliability.

Common Overlap Mistakes in Bitumen Waterproofing Projects.

- Inadequate heating of SBS membrane overlaps

- Installing self-adhesive membranes on damp substrates

- Insufficient overlap width

- Poor compaction leading to air pockets

- Ignoring reinforcement at stress-prone areas

- Avoiding these mistakes significantly reduces the risk of early leakage and system failure.

What Defines a High-Quality Overlap in Bitumen Membranes?

A properly treated overlap should demonstrate:

- Continuous and uniform bonding .

- No wrinkles, bubbles, or voids .

- Strong adhesion even under temperature changes .Long-term resistance to water penetration .

These characteristics ensure that the waterproofing system performs reliably throughout its service life.

Conclusion: Overlap Quality Determines Waterproofing System Performance .

In SBS and self-adhesive bitumen waterproofing systems, overlap treatment is not a minor detail—it is a decisive factor. Proper preparation, correct application methods, and compatible materials are essential to achieving a durable and leak-free waterproofing solution.

For contractors and project owners, investing attention in overlap treatment directly translates into longer service life and reduced maintenance costs.